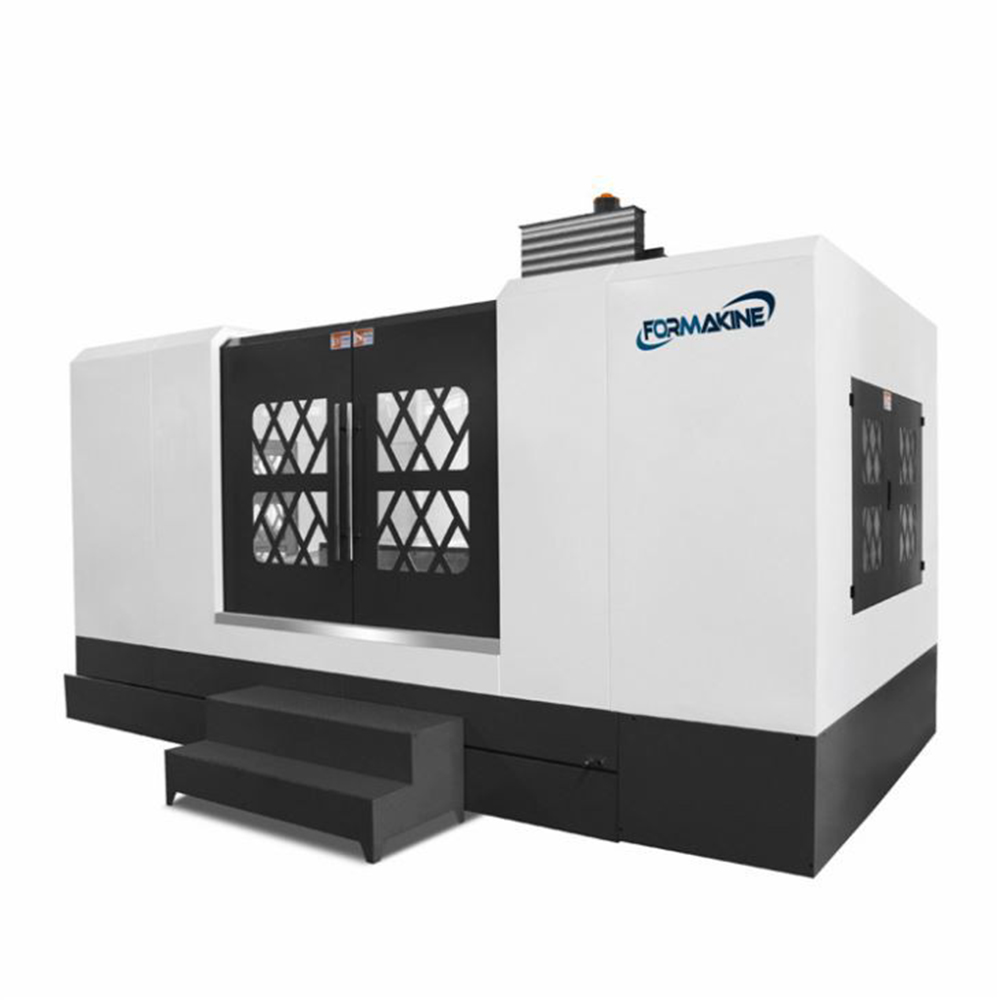

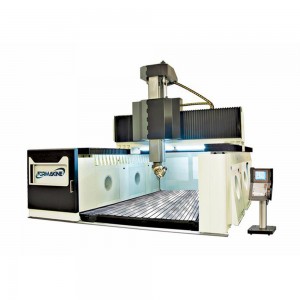

High Precision Vertical Machining Center

Technical Parameters

| Parameter | Unit | FM-850V |

| X/Y/Z Axis Travel | Mm | 800*500*500 |

| Table Size | Mm | 900*500 |

| T Slot | Mm | 5-18*90 |

| Max Load On Table | Kg | 600 |

| Spindle Center To Column | Mm | 485 |

| Spindle Nose To Table | Mm | 130-630 |

| X/Y/Z Axis Motor | KW | 2.0/2.0/3.0 |

| X/Y/Z Rapid Feed | M/Min | 48/48/48 |

| Controller | Mitsubishi M80A/M80B Fanuc: 0i-MF/Siemens 828D | |

| Spindle Taper | BT40-Φ140 | |

| Spindle Speed | Rpm | 10000 |

| Spindle Motor | HP | 15(11KW) |

| Positioning Accuracy | Mm | ±0.003/300 |

| Repeated Accuracy | Mm | ±0.002/300 |

| Air Pressure | Kg/Cm² | 6~7bar |

| Dimension | Mm | 2700x2700x2920 |

| Weight | Kg | 5500 |

Main Configuration

| Standard Accessories | Optional Accessories | ||

| Item | Name | Item | Name |

| 1 | Mitsubishi M80B Controller System | 1 | Mitsubishi M80A Controller |

| 2 | BT40 7.5kw 10000rpm Belt Drive Spindle | 2 | Fanuc 0i-MF Controller |

| 3 | Spindle Blowing System | 3 | Siemens 828D Controller |

| 4 | Spindle Oil Cooler | 4 | Fanuc 15kw / 18.5kw Spindle Motor |

| 5 | Automatic Centralized Lubrication System | 5 | Fanuc 3 Axis 3.0/3.0/3.0kw Motor |

| 6 | Pneumatic System | 6 | Fanuc 3 Axis 4.0/4.0/4.0kw Motor |

| 7 | Coolant Flushing System | 7 | Fanuc 3 Axis 4.0/7.0/4.0kw Motor |

| 8 | Heat Exchanger For Electrical Cabinet | 8 | Mitsubishi 11kw / 15kw Spindle Motor |

| 9 | Rear Chip-Removal Device | 9 | Mitsubishi 3 Axis 3.0/3.0/3.0kw Motor |

| 10 | Operation Manuals | 10 | Mitsubishi 3 Axis 4.5/4.5/4.5kw Motor |

| 11 | Alarming Light | 11 | 10000/12000/15000rpm Direct Drive Spindle |

| 12 | Work Light | 12 | Coolant Through Spindle |

| 13 | Full Enclosed Cover | 13 | Taiwan Spinture Spindle |

| 14 | Guideway Cover | 14 | BT40 24T/30T Arm Type Tool Magazine |

| 15 | 4th Axis Interface | 15 | Chian Type Chip Conveyor |

| 16 | Automatic Power-Off | ||

| 17 | 4th Axis Rotary Table | ||

Picture Display

|

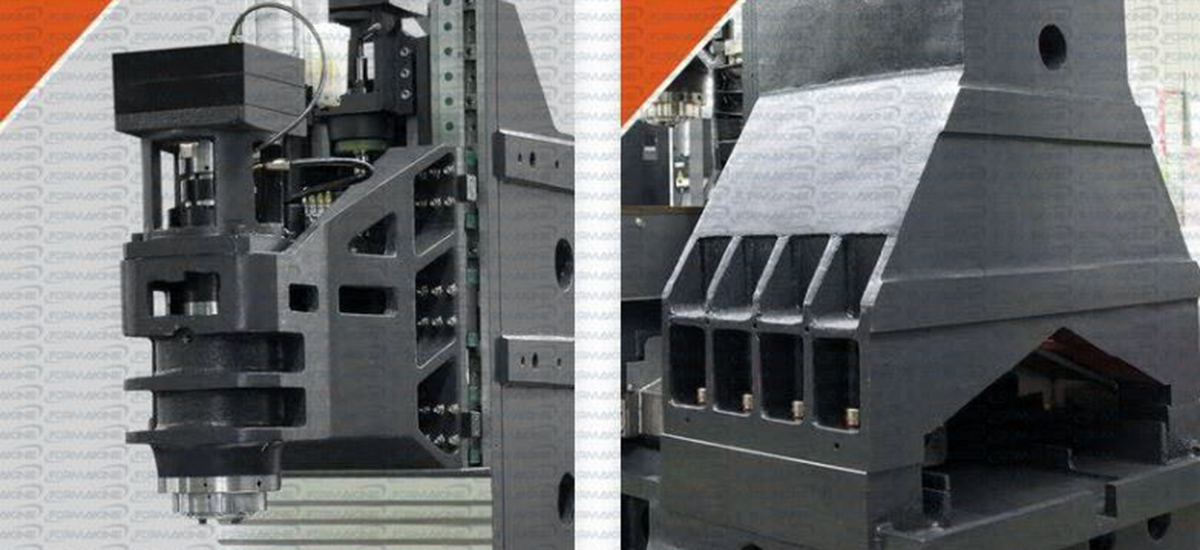

Machine head Strengthened cross-ribs to increase bending and torsion resistance. |

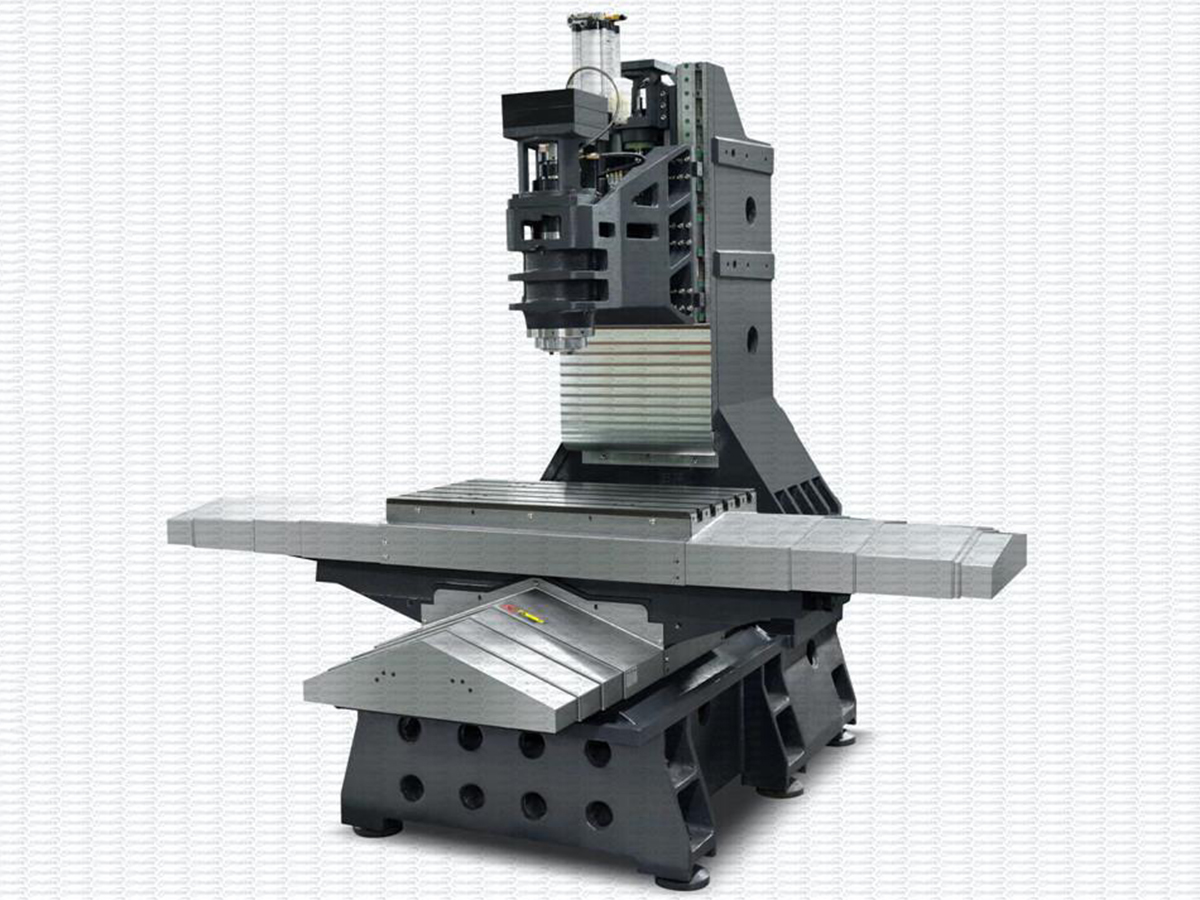

Column Box structure large span A type column with high rigidityto ensure stability during machining. |

|

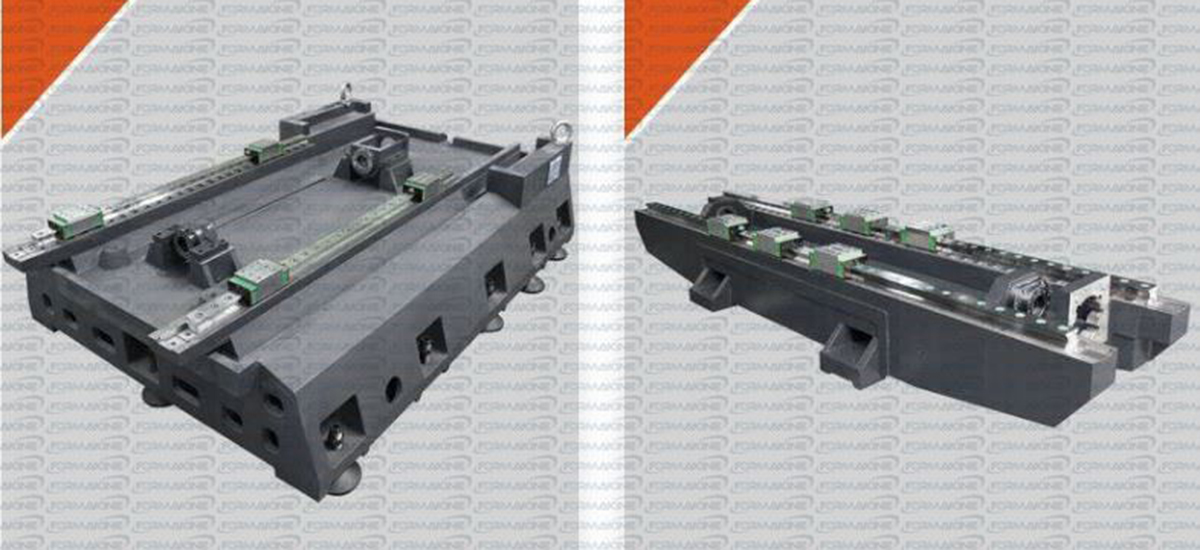

Base Double layered box type base to ensure high stability and rigidity. |

Saddle Double T extra-wide structure to improve rigidity and stability during rapid feed. |

|

Spindle head Box structure spindle head to increase cutting rigidity 48m/min. |

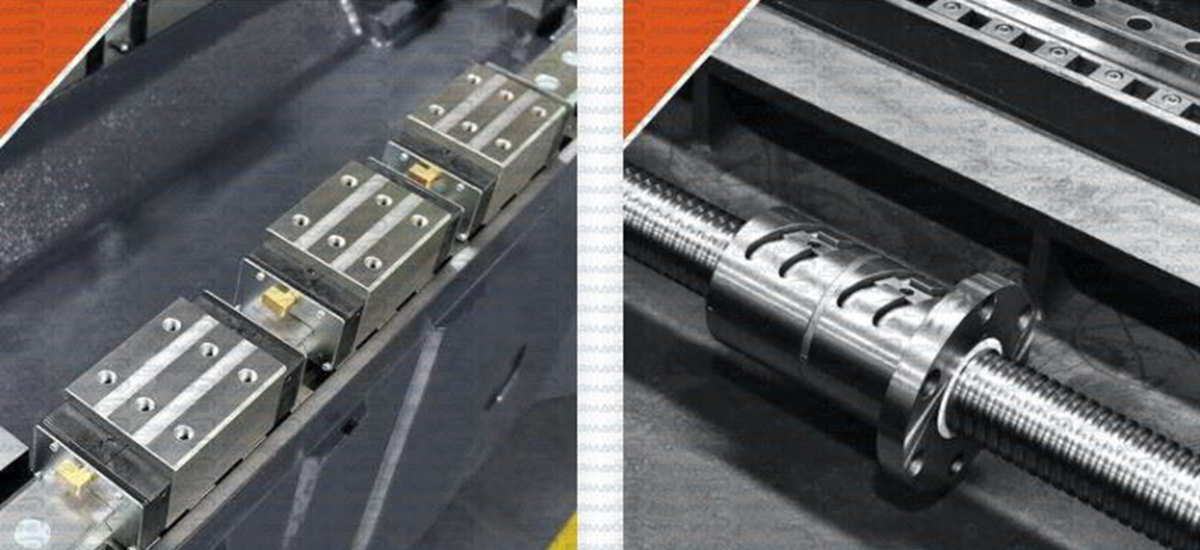

Guide way 3 axis ball/roller linear guideway, rapid feed is improve the machining efficiency. |

|

Slider Z axis 3 sliders to increase the stability improve the transmission rigidity and machine accuracy. |

Screw C3 grade high precision ball screw with pre-extension process, and accuracy during machining. |

|

Spindle Belt/direct drive spindle with spindle oil coolant and blowing system to ensure spindle precision and stability under high speed running. |

Controller system Mitsubishi/Fanuc/Siemens controller system optional. |

◆Kindly notice that configuration and appearance are subject to fine products.

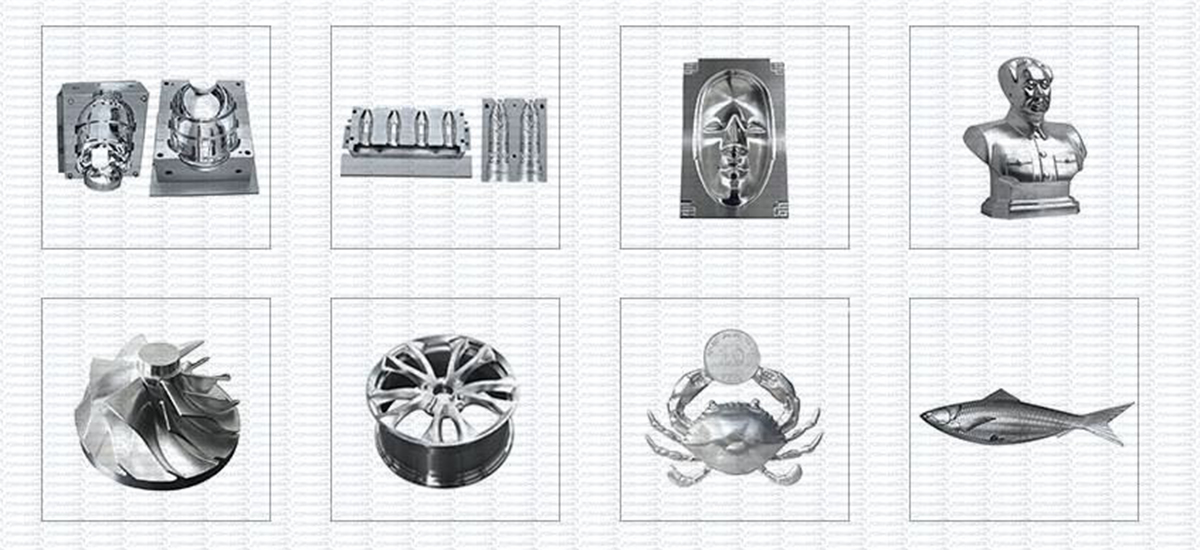

Applications

High Precision Series

It can continuously complete drilling, milling, tapping, boring, reaming and other machining processes by once clamping, and can complete coordinate boring and fine machining of complicated parts and molds accurately and efficiently. This series of machine is widely used for mass production of small and medium-sized cabinets, covers, panels, shells and plates in high-precision molds, automobiles, machinery, aviation, aerospace, instrumentation, light industrial textiles, electronic instruments, precision metal products, precision mold products and machinery manufacturing industries.