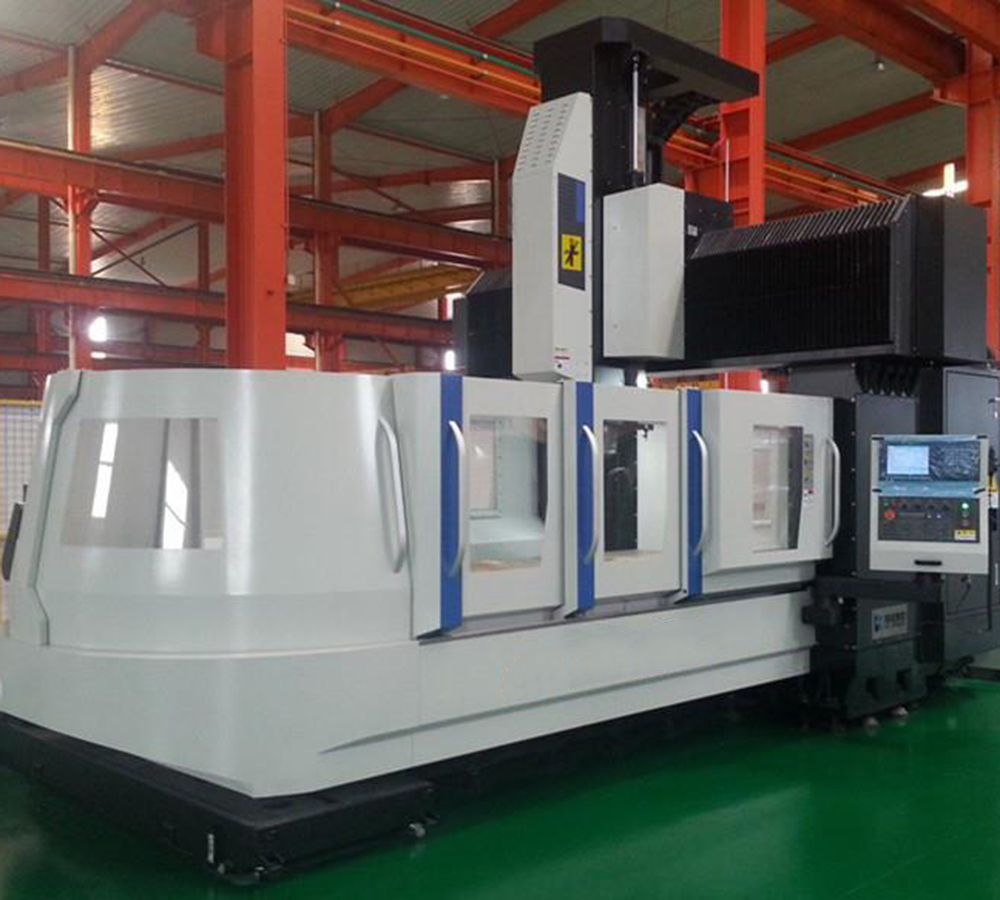

Portal CNC Milling Machining Center

Product Description

Portal CNC Milling Machine Center

Widely used in the aviation, auto, precision molding industries. It can provide a high-performance mechanical system and a software interface which can be operated easily. This provides multiple choices that will allow you to fully realize the high precision dream.

Technical Parameters

|

Specifications |

|

|||

|

Machine Type |

Unit |

YFM2018 |

YFM2518 |

YFM3018 |

|

Worktable |

||||

|

Worktable (Length×Width) |

Mm |

2000×1500 |

2500×1500 |

3000×1500 |

|

Maximun Load Of Table |

Kg |

8000 |

10000 |

12000 |

|

T-Slot |

Mm |

7-22×200 |

||

|

Triaxial Itinerary |

||||

|

Gantry Width |

Mm |

1800 |

||

|

Travel For X/Y/Z Axis |

Mm |

2000/1800/900 |

2500/1800/900 |

3000/1800/900 |

|

Distance From Spindle Nose To Table Surface |

Mm |

150-1050 |

||

|

Feed System |

||||

|

CNC System |

|

FANUC Oi MD |

||

|

Rapid Shift Of Axis Of X/Y/Z |

M/Min |

12/12/10 |

||

|

Maximun Cutting Feed Speed |

M/Min |

7 |

||

|

Automatic Tool Transform System (CNC Milling Without) |

||||

|

Standard Tool Quantity |

Piece |

BT50/24 |

||

|

The Larges Diameter Cutter Knife/Length |

Mm |

Φ110/300 |

||

|

Tool Exchanging Manner |

|

Pneumatic |

||

|

Maximum Tool Weight |

Kg |

18 |

||

|

Precision |

||||

|

Positioning Accuracy |

Mm |

0.021 |

||

|

Accuracy Of Repeated Positioning |

Mm |

0.02 |

||

|

Guide Form And Specifications |

||||

|

X/Y/Z-Axis Guide Specifications |

|

2-55(X)/2-55(Y)/Z Axis Hard Rail |

||

|

Spindle System |

||||

|

Spindle Specifications |

|

BT50/Φ190 |

||

|

Speed With Belt Drive Milling Head |

R.P.M |

6000 |

||

|

Motor Power Of Spindle |

Kw |

15/18.5 |

||

|

Air Pressure |

||||

|

Requirements For Air Compressing |

Kg/Cm² |

≥6 |

||

|

Air Pressure Flux |

M³/Min |

≥0.5 |

||

|

Machine Specifications |

||||

|

Integrated Weight |

Kg |

19000 |

21000 |

23000 |

|

Overall Dimension (Length×Width×Height) |

Mm |

6195×4200×4580 (Travel Peak) |

71400×4200×4580 (Travel Peak) |

8150×4200×4580 (Travel Peak) |

|

Standard Fittings |

|||

|

FANUC Control System |

Water Tank Cooling Device |

Working Lamp |

Outer Protective Cover |

|

Three-Color Warm Lamp |

LCD |

Tool Box |

Operating Manual |

|

Spindle Blowing Device |

Handheld Air Gun |

Electric Control Cabinet |

Transformer |

|

Pneumatic Part |

Sprial+Chain Chip Cleaner |

Spindle |

Screw |

|

Heat Exchanger For Electrical Cabinet |

RS-232 Standard Output Interface |

Automatic Lubricating Device |

Manual Pulse Generator |

|

Optional Fittings |

|||

|

CNC System Siemens/ Mitsubishi |

Automatic Tool Changer Disc Type / Chain Type |

Water Outlet From Spindle Center |

Disc Type Oil-Water Separator |

|

Air Conditioner For Electrical Cabinet |

Full-Enclosed Optical Scale Detecting System |

Automatic Tool Length Measuring System |

Manual/Semi-Automatic Right-Angle Head |

|

X/Y/Z Axis Optical Scale |

Toolholder In Oilway |

Oil Mist |

ZF Gearbox |

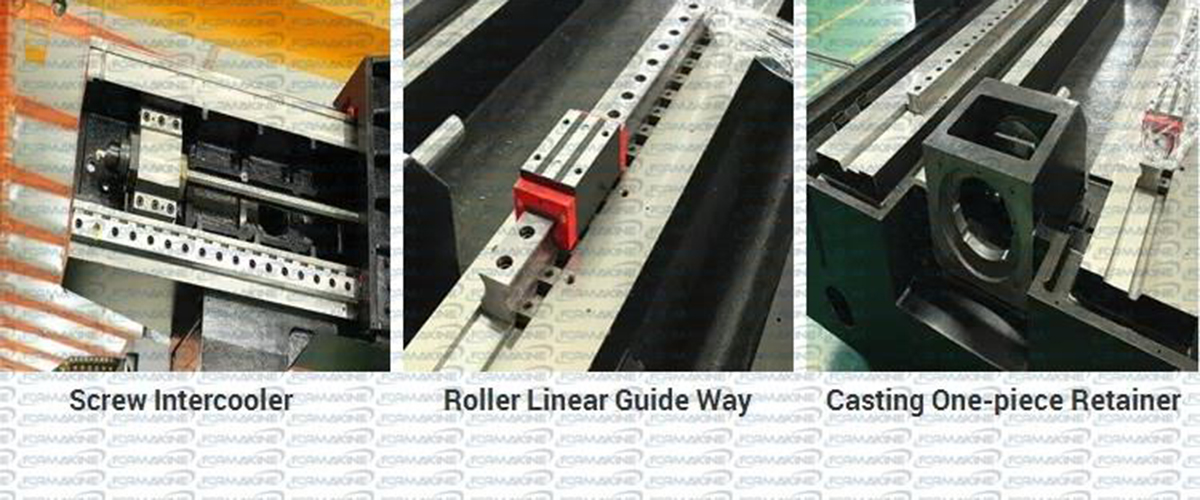

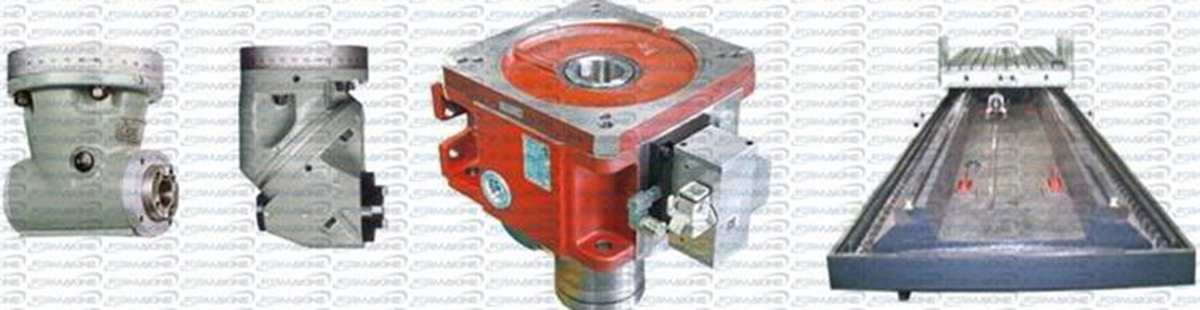

Picture Display

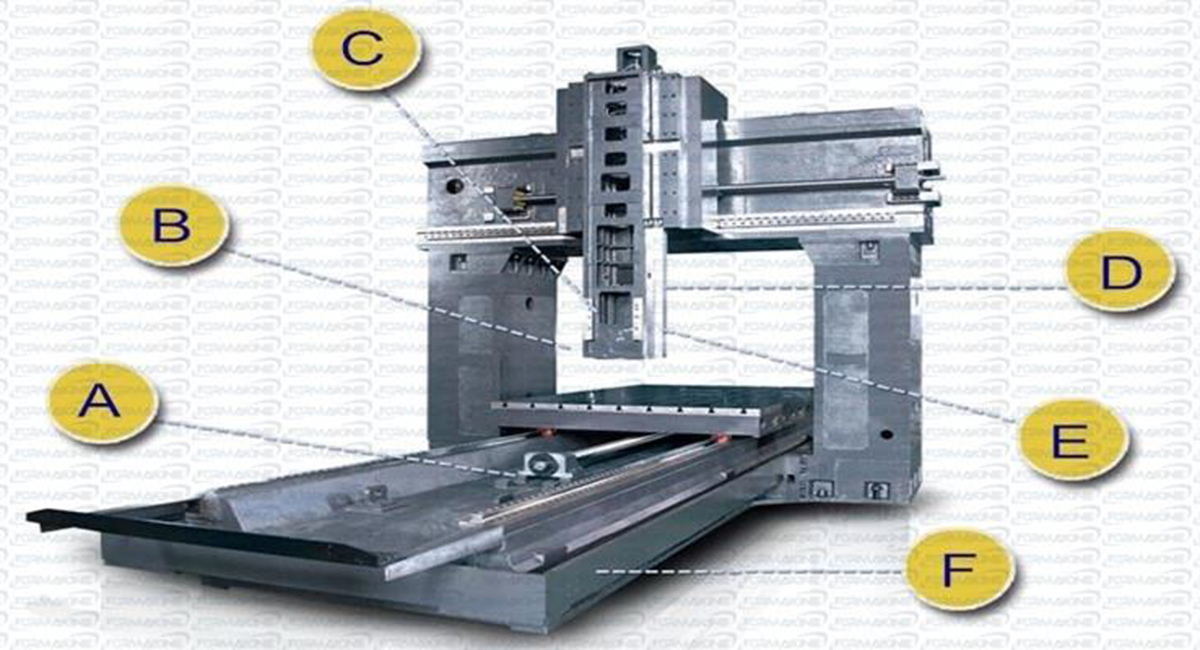

Structure

The structure of machine tool is analyzed with ANSYS at all stages from foundation design to guarantee of high-speed and high-precision continuous machining. A simulation test for deformation produced when the center of machine tool bears load is conducted to guarantee excellent bending rigidity of machine tool.

|

Optional external encoder realizes closed loop control |

Screw supporting structure is designed for above more than 5 meters (including 5 meters) gantries. |

All gear form main transmission is optional. The optional Z axis rails rail pretensioning structure the patent technology |

|

Optional 90° milling head realizes five-face machining. Optional universal milling head realizes multi-angle machining |

Optional German ZF gearbox widens machining range. |

As standard each Formakine gantry machining center is equipped with two spiral chip cleaners and one chain chip cleaner. |

Our Factory

Packing & Shipping