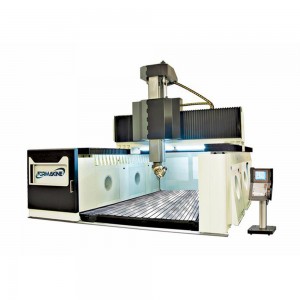

CNC Gantry Machining Center

Product Description

The Main Performance Characteristics:

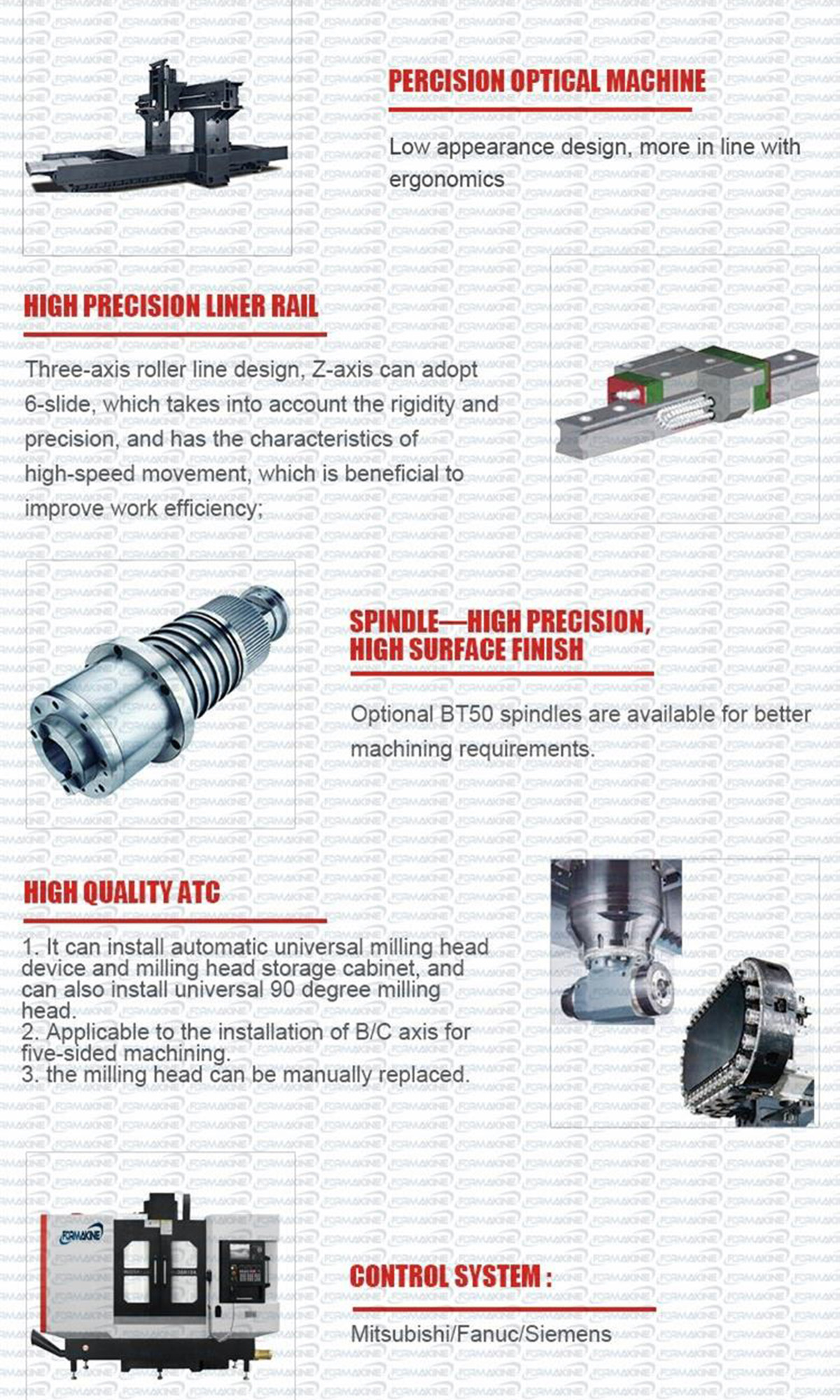

1 The spindle of the machine tool adopts the high precision spindle assembly, the belt type milling head, the main shaft is the servo motor drive. X, Y, Z axis servo control, the direct connect architecture, with automatic lubricating system, machine tools to achieve a rapid motion; X, Y, Z three directions to feed with high accuracy high strength ball screw, high feed speed; driving motor through flexible coupling with screw direct coupled, servo servo motor directly deliver power to the high precision ball screw, no backlash to ensure the positioning precision of the machine tool.

2 Taiwan famous brand spindle with high speed and high precision, high rigidity spindle unit, axial and radial load capacity, speed up to 6000rpm; the center of spindle blowing structure, with rapidly in the tool release after cleaning of the spindle cone center of high pressure gas, to ensure the accuracy of tool clamping;

3. X, Y, Z axis servo control, direct coupled structure is adopted in the Taiwan high precision and high intensity of ball screw, screw installation of pre stretching, connecting rigidity, high feed speed; the servo motor directly transferring power to a high precision ball screw, no backlash, ensure the machine tool positioning accuracy. The Z shaft is provided with a hydraulic balancing device, which ensures.

4 Y, X, Z three direction guide rails, the lead screw all uses the airtight protection, guarantees the lead screw and the guide rail clean, guarantees the machine tool transmission and the movement precision;

5 the outer protection of the machine tool is designed with the ring structure, which is safe and reliable;

6. Machining center configuration: the Taiwan high quality of 16 or 20 knife bevel knife library, the shortest path tool change, tool change accurately, short time, high efficiency, the test run, in line with the reliability requirements;

7 using the centralized automatic lubrication device, timing, quantitative automatic intermittent lubrication, stable and reliable work;

8 the machine electrical system wiring neatly, the structure is reasonable, the electric box seal is good, is equipped with the heat exchange system, guaranteed the good use environment;

9. CNC system (FANUC, Mitsubishi, Siemens, wide number) can be selected. The system has perfect and reliable interlocking, safety protection and fault diagnosis and alarm functions, equipped with RS232 communication interface;

10 the machine is easy to operate, flexible and quick.

Application

This machine is used in CNC milling, boring, drilling, tapping, processing of steel, cast steel, cast iron etc.. Machine tool accessory head to realize the of all kinds of plate, plate, shell and mould for complex parts in a fixture in complete drilling, milling, boring, reaming, reaming, tapping a variety of processes. It can be used for small batch spare parts, processing and manufacturing, of complex, high precision parts processing more show its superiority, also can compose the automatic production line for mass production, to ensure the parts of product quality and efficient production.

Technical Specifications

| Specifications | Units | YH2312 |

| Table Size | Mm | 1200x2000 |

| Max. Load Working Table | Kg | 2500 |

| Gantry Width | Mm | 1600 |

| T-Type Slot Numbers / Width /Space | Mm | 7-22x170 |

| The Moving Direction Of Travel Of Working Table | Mm | 2100 |

| The Sliding Seat Moving Direction Of Travel | Mm | 1600 |

| Spindle Up And Down Movement Direction Travel | Mm | 800 |

| Distance From Spindle End To Platform | Mm | 115-915 |

| Spindle Specification (Model / Installation Diameter) | Mm | BT50-Φ190 |

| Spindle Speed | R/Min | 6000 |

| Fast Moving X.Y Axis | Mm/Min | 10000 |

| Fast Moving Z Axis | Mm/Min | 5000 |

| Feed Speed (X.Y.Z) | Mm/Min | 5-5000 |

| Spindle Motor Power | KW | 22 |

| X.Y.Z Shaft Motor Torque | N. M | 30/22/22 |

| X.Y Axis Positioning Accuracy | Mm | 0.020 |

| Z Axis Positioning Accuracy | Mm | 0.018 |

| X.Y Axis Repeat Positioning Accuracy | Mm | 0.010 |

| Z Axis Repeat Positioning Accuracy | Mm | 0.010 |

| Tool Magazine Capacity | Piece | 16 |

| X/Y Axis Guide Rail | 55 Specification Rolling Guide | |

| Z Axis Guide Rail | Sliding Guide | |

| Weight Of Machine Tool | T | 28 |

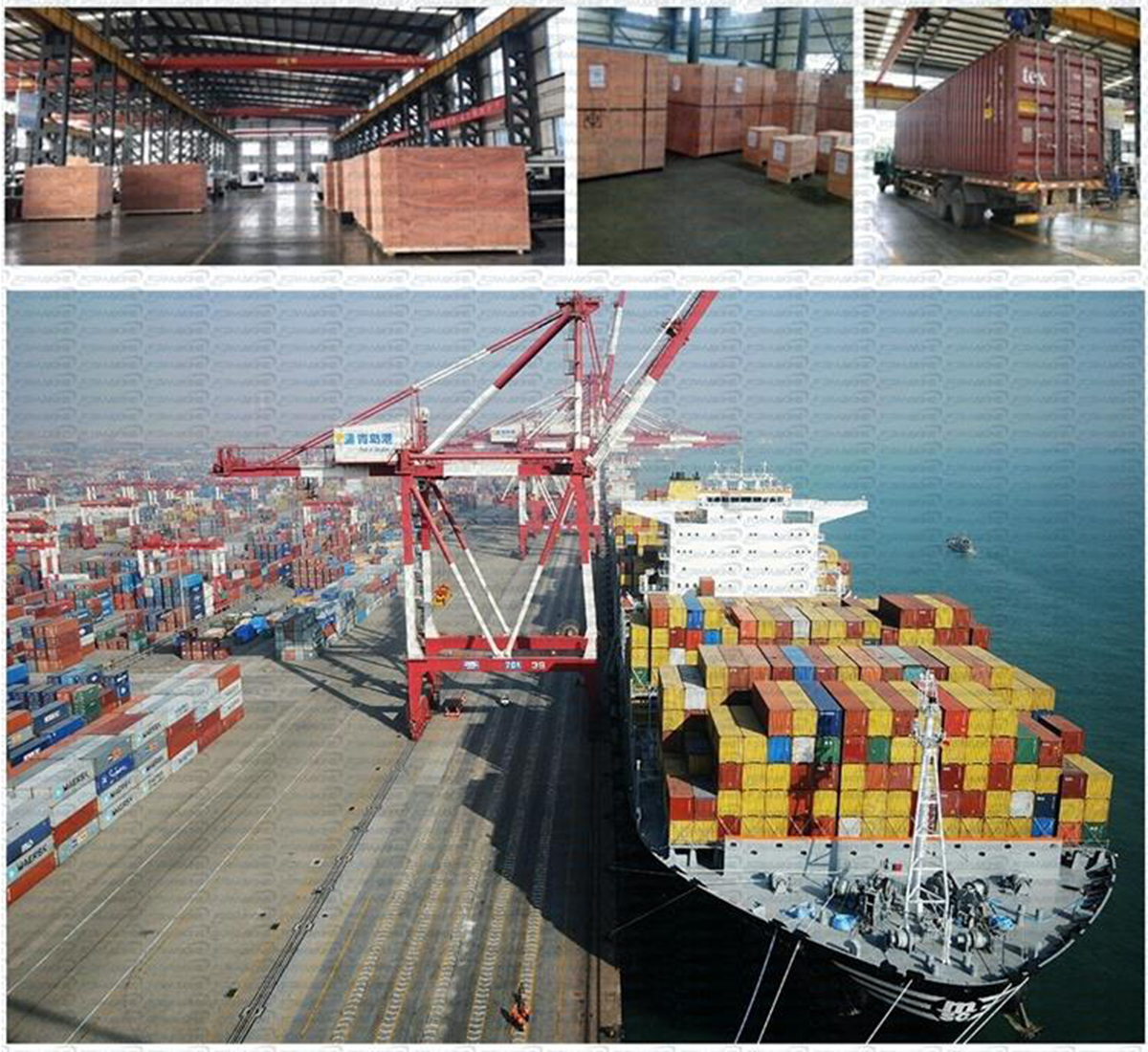

Packing & Shipping