Semi Automatic CNC Guillotine Shearing Machine

Product Description

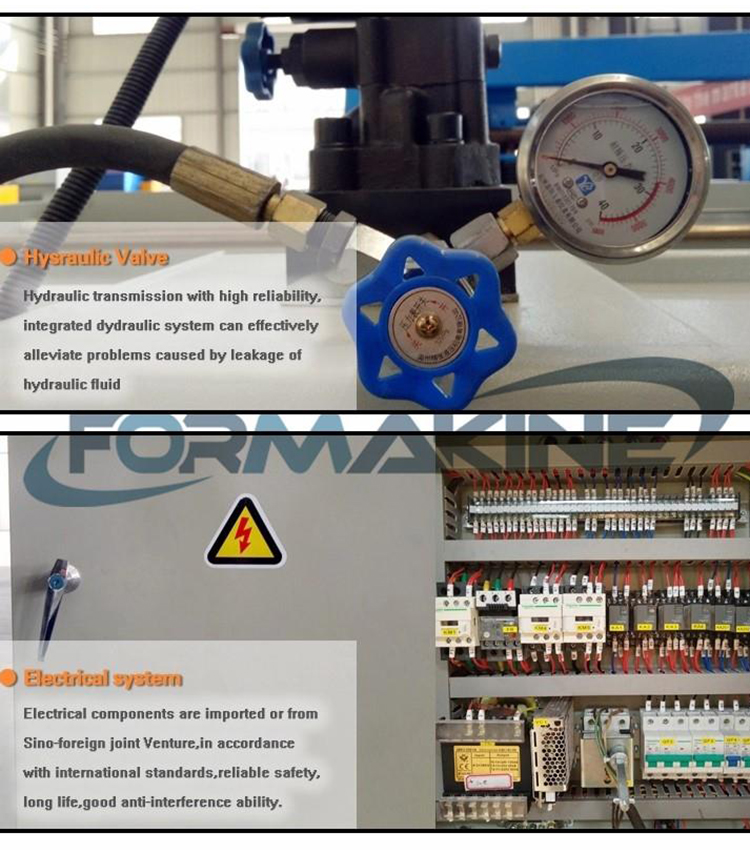

Hydraulic transmission, pendulum-type tool holder. The overall welding of the frame is hard and durable, and the use of a nitrogen cylinder returns smoothly and rapidly.

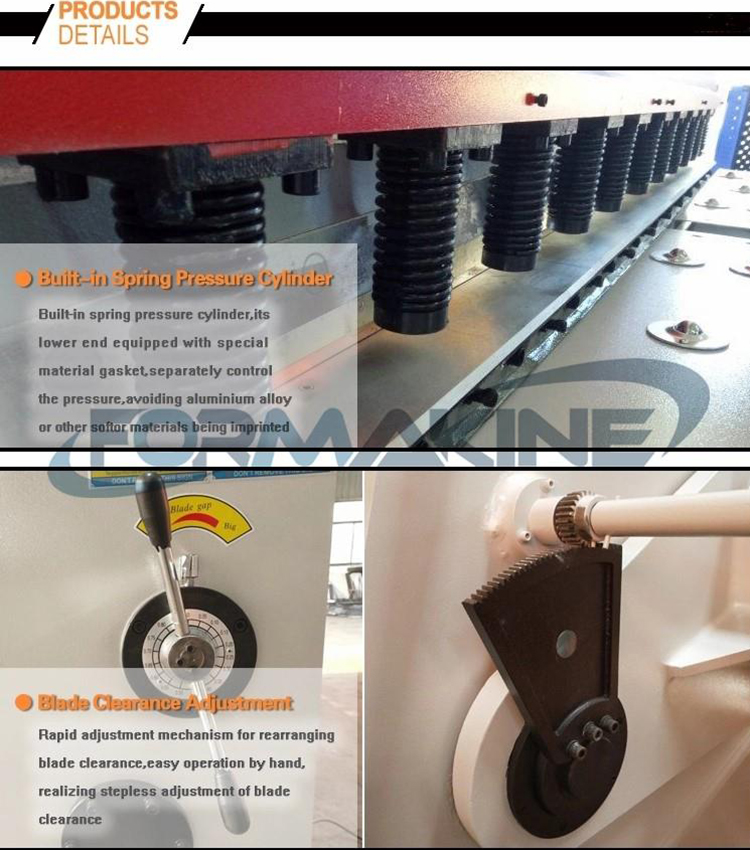

It has the function of stepless adjustment stroke. The amount of upper and lower blade edge clearance is adjusted by the handle, and the gap of the blade is even and rapid.

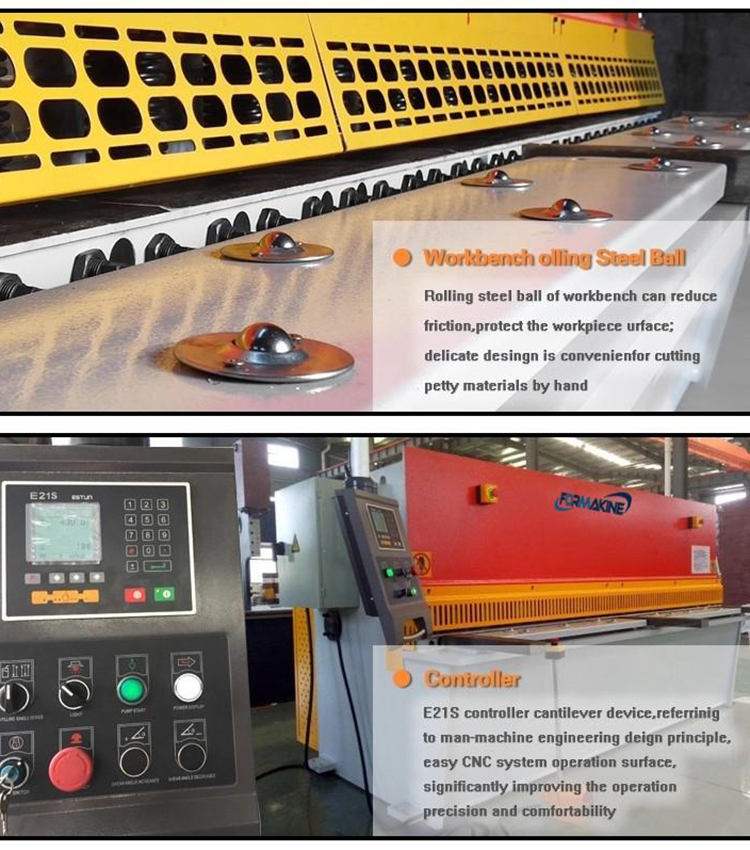

NC control system and position encoder, inverter, closed-loop control system, speed, high positioning accuracy, good stability, can accurately ensure the accuracy of the back gauge displacement size, while the CNC system has precision compensation and automatic detection A variety of additional features.

STANDARD EQUIPMENTS

√ Hardened blades.

- Top blades : 2 sides

- Bottom blades : 4 sides

√ E21S controller.

√ 250mm throat depth.

√ 600mm motorized backgauge system with 0,1 mm accuracy.

√ 800mm side gauge and front support arms.

√ Metric and inch rulers.

√ Front, side and back safety panels which are suitable for CE norms.

√ Sheet sliding system.

√ Schneider Electric System.

√ Rexroth hydraulic system.

√ Hold down cylinders.

√ Moveable foot pedal.

√ Manual blade gap adjustment.

√ Emergency stop button.

√ Collapsible finger protection.

OPTIONAL EQUIPMENTS

√ Optional throat depth.

√ Front angle gauge.

√ Side gauge and front support arms in optional lengths.

√ Sheet conveyor and stacking system.

√ Front Gauge X1, X2 axis and backgauge X3, X4 axis.

√ Optional backgauge stroke.

√ Sheet support system for thin sheets.

1- Pneumatic support system. (Lever type)

2- Pneumatic support system. (Monobloc panel type)

√ Hydraulic oil cooling and heating system.

√ Optional solid table.

√ Stainless steel blades.

√ Ability to increase stroke amount per minute.

√ Light safety system for finger protection.

√ Optional alternative colors.

√ Coolant system or heater can be placed in electric panel during ambient conditions.

√ Double foot pedal.

√ Electrical panel or controller can be placed on right side of the machine.

√ Laser cutting line.

√ Central lubrication system.

Technical Parameters

| No | Model | Max Cut Thickness | Max Cut Length | Ram Stroke | Cutting Angle | Motor | Machine Szie |

| Mm | Mm | N/Min | ° | Kw | Mm | ||

| 1 | 4x2500 | 4 | 2500 | 20-40 | 0.5-1.5 | 5.5 | 3100x1600x1700 |

| 2 | 4x3200 | 4 | 3200 | 20-40 | 0.5-1.5 | 7.5 | 3800x1800x1700 |

| 3 | 6x2500 | 6 | 2500 | 16-35 | 0.5-1.5 | 7.5 | 3150x1650x1700 |

| 4 | 6x3200 | 6 | 3200 | 14-35 | 0.5-1.5 | 7.5 | 3860x1810x1750 |

| 5 | 6x4000 | 6 | 4000 | 10-30 | 0.51.5 | 7.5 | 4630x2030x1940 |

| 6 | 6x5000 | 6 | 5000 | 10-30 | 0.5-1.5 | 11 | 5660x2050x1950 |

| 7 | 6x6000 | 6 | 6000 | 8-25 | 0.5-1.5 | 11 | 6680x2200x2500 |

| 8 | 8x2500 | 8 | 2500 | 14-30 | 0.5-1.5 | 11 | 3170x1700x1700 |

| 9 | 8x3200 | 8 | 3200 | 12-30 | 0.5-1.5 | 11 | 3870x1810x1780 |

| 10 | 8x4000 | 8 | 4000 | 10-25 | 0.5-1.5 | 11 | 4680x1900x1860 |

| 11 | 8x5000 | 8 | 5000 | 10-25 | 0.5-1.5 | 15 | 5680x2250x2200 |

| 12 | 8x6000 | 8 | 6000 | 8-20 | 0.5-1.5 | 15 | 6800x2350x2700 |

| 13 | 10x2500 | 10 | 2500 | 10-25 | 0.5-2.0 | 15 | 3270x1730x1800 |

| 14 | 10x3200 | 10 | 3200 | 9-25 | 0.5-2.0 | 15 | 3990x2250x2200 |

| 15 | 10x4000 | 10 | 4000 | 6-20 | 0.5-2.0 | 15 | 4720x2490x2500 |

| 16 | 10x5000 | 10 | 5000 | 7-20 | 0.5-2.0 | 22 | 5720x2600x2800 |

| 17 | 10x6000 | 10 | 6000 | 6-20 | 0.5-2.0 | 30 | 6720x2500x2550 |

| 18 | 12x2500 | 12 | 2500 | 10-25 | 0.5-2.0 | 15 | 3270x1730x1800 |