Electro Hydraulic Bending Machine

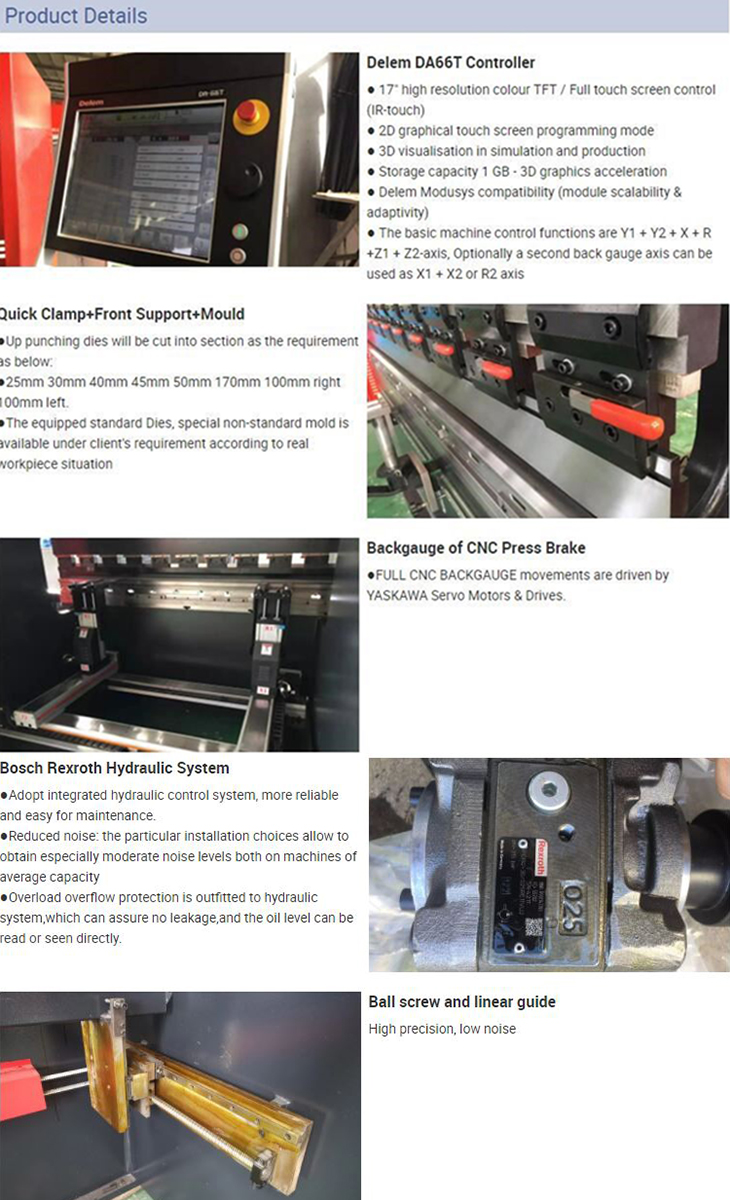

Performance And Features

1. All steel-welded structure, the tempering treatment to eliminate the internal stress of steel, with high strength and good rigidity.

2. The machine frame, slide, table and other major parts are using the large-scale NC boring and milling machine, with one-time clamping and refined processing, guarantees the precision requirements of the operator.

3. We adopted LVD company's technology, and developed the long rails bending machine, which has ability to hold partial load, especially suitable for thin plate bending. The design of work table, column, beam, slider use higher stiffness parts, workpiece deformation is small when working, therefore, the workpiece has good linearity and angle.

4. Adopts OMG USA or Germany Bosch Rexroth hydraulic system, stable and reliable performance. Hydraulic top-drive, imported seals to insure steadiness and reliability. Mechanical stop, steel torsion bar to maintain synchronization, high precision.

5. Deflection compensation unit installed on the top die. Manual crowned bottom die holder is adopted for the machine above 250 ton and 4000mm in length.

6. The machine tool guide rail adopts an advanced self-lubricating materials, lubrication and maintenance does not need frequently.

7.Upper moving bending design, stable working, convenient operation, and safety guaranteed.

8. Motorized-adjusting device of back gauge and ram stroke, fine adjusting by handwheel, numerical display.

9. Stabilizes left and right balance under of the Torsion Bar.

10. Back gauge with ball screw, liner guide is optional.

11. A set of standard tools is provided with each machine.

Picture Display