1000W Dual Drive Fiber Laser Cutting Machine

Product Features

1.In order to meet the increasingly complex needs of consumers, We are targeted at market demand, independently developed this sheet metal and pipe integrated laser fiber cutting machine, one machine dual purpose, this machine solves double cutting needs by one time.

2. Low cost and the power consumption is 0.5-1.5kw/h; Customer can cut all kinds of metal sheets by blowing air;

3. High-performance. Imported the original packaged fiber laser, with stable performance and the lifespan is over 100,000 hours;

4. High speed and efficiency, the speed of cutting metal sheets close to tens of meters;

5. The laser maintenance free;

6. The cutting edge looks perfect and the appearance is smooth and beautiful;

7. Imported the transmission mechanism and servo motor, and high cutting accuracy;

8. Dedicated software enables graphic or text to be instantly designed or processed. Flexible and easy operation.

Application

Applicable Materials For Laser Cutting Machine For Metal

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries

Fiber Laser Cutting Machine is widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc

Cutting Ability

specially used in cutting 0.5~14mm carbon steel,0.5~10mm stainless steel,galvanized plate

lectro-Galvanized Steel,silicon steel,0.5~3mm aluminium alloy,0.5~2mm brass and red copper etc thin metal sheet (The laser brand can be customized, power optional from 500w-3000w )

Technical Specifications

| Machine Model | FM3015 |

| Laser Type | Import Original Fiber Laser |

| Laser Power | 500W 750W 1000W (Optional) |

| Weight | 3000kg |

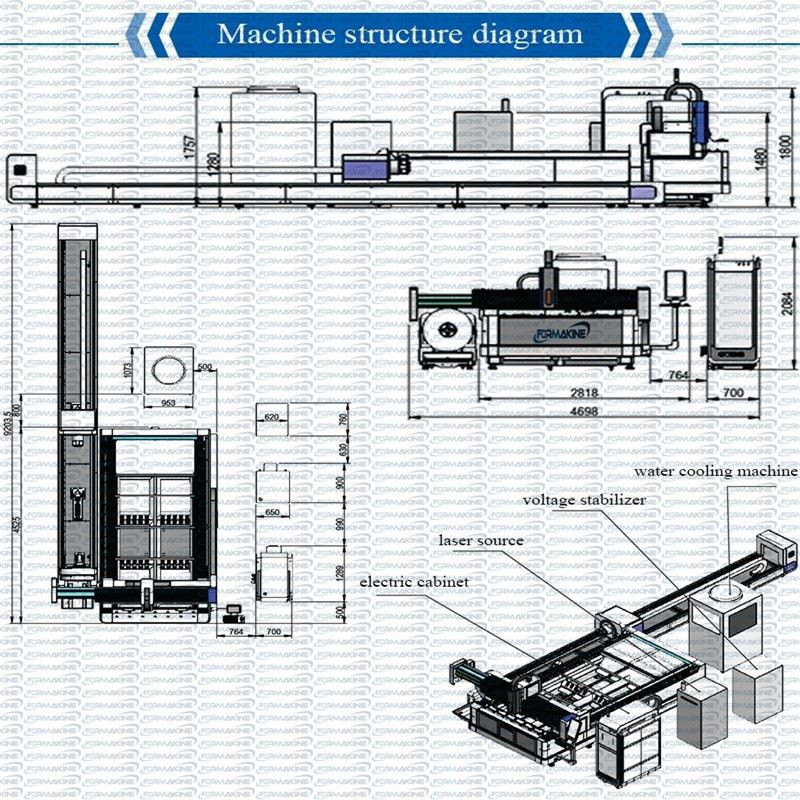

| Dimensions | 4440mm×2500mm×1860mm |

| Working Area | 3000×1500mm |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Speed | 80m/Min |

| Maximum Acceleration | 1G |

| Transmission | Double Driver Rack Gear |

| Power Consumption | <10KW |

| Power Supply | 380V/50Hz/60Hz/60A |

Cutting Speed

| Material | Thickness(MM) | Speed(Meter/Min) | Pressure(MPA) | Focus |

| 201 SS | 1 | 9 | 0.8 | -4 |

| 201 SS | 2.2 | 2 | 1.2 | -4 |

| 304 SS | 1.3 | 7 | 0.9 | -4 |

| 304 SS | 1.8 | 3 | 1 | -4 |

| Carbon Steel | 1.1 | 9(10) | 0.8 | -1 |

| Carbon Steel | 2.4 | 2.2 | 0.4 | -3 |

| Carbon Steel | 2.8 | 1.5 | 0.4 | -3.5 |

| Carbon Steel | 4 | 1.5(1.2) | 0.4 | -4 |

Main Configuration

Configuration for fiber metal laser cutting machine

3000*1500mm working area;

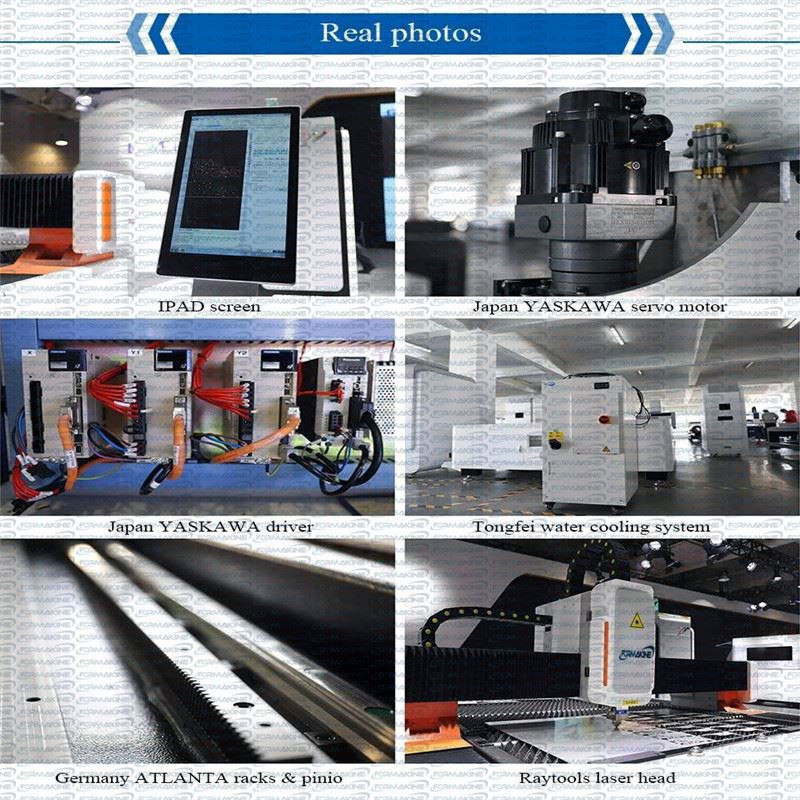

Switzerland Raytools laser cutting head;

X,Y axis Japan YASKAWA servo motor;

Z axis Japan Panasonic servo motor;

Taiwan HIWIN guide rail;

Taiwan YYC gear rack;

France MOTOREDUCER reducer;

Taiwan TBI ball screw;

Japan SMC /Taiwan AirTac pneumatic components;

France Schneider electrical components;

Tongfei water chiller;

Cypcut control system;

Gross weight 5000kg;

Quality Control

Each machine has passed the strictly quality control, inculding the purchased parts and parts.

Quality Is our paramount mission that underpinning the lifeline of the company, and it is the most important factor to maintain long-term business relationships with customers. Special attention is paid to the quality of every unit of Fiber Laser Cutting Machine. Standard quality control system and team are responsible to insure the product quality in every process with different instruments like laser interferometer and laser power meter. The laser interferometer and laser collimator are used through the mechanical assembling process. In the laser assembling process,the laser power meter and optical microscope are adopted.

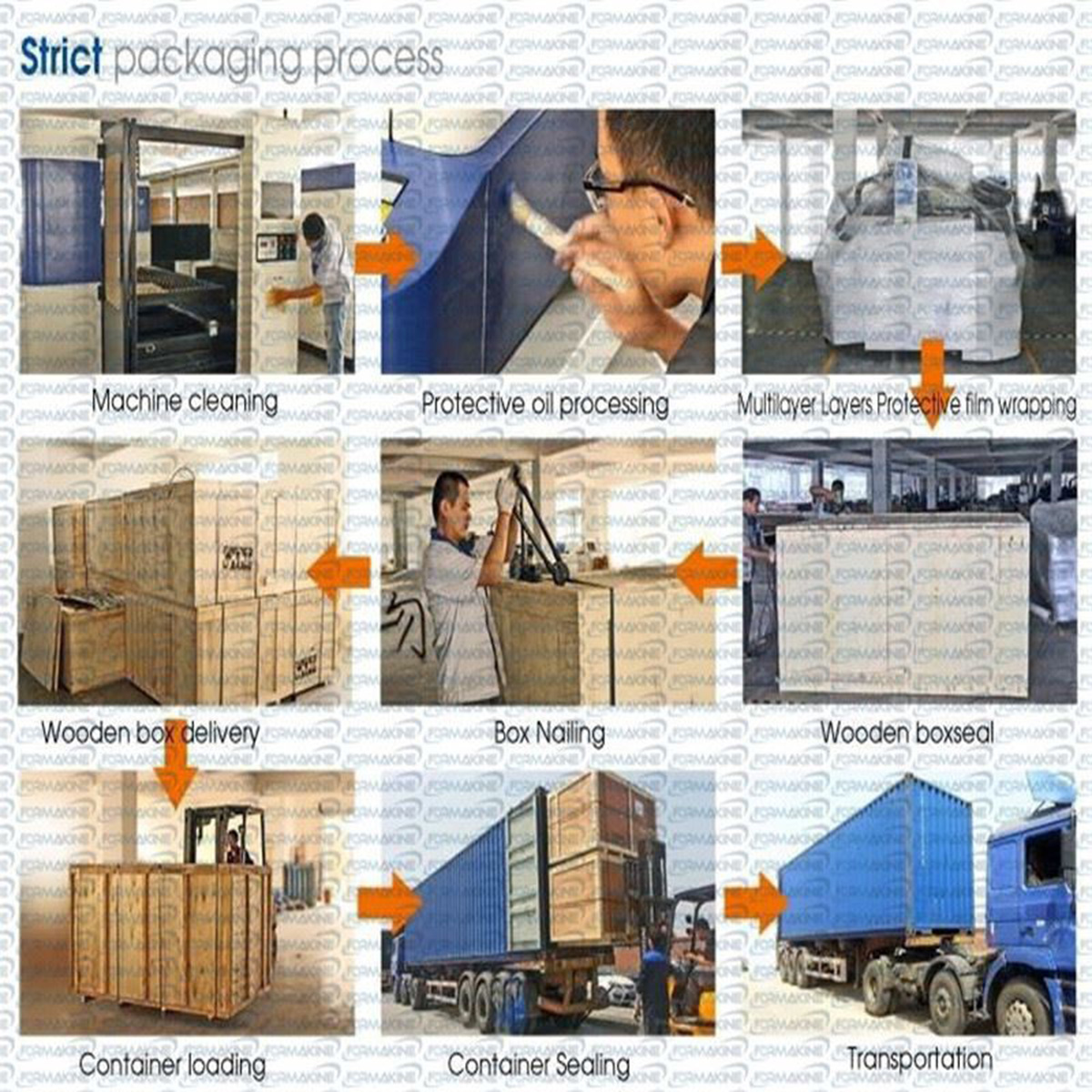

Packing & Delivery