Full Automatic Hydraulic Pipe Bending Machine

Product Description

Standard Equipment:

Plate Support Arms

Germany Bosch-Rexroth Hydraulic

Germany EMB Tubing connector

Germany Siemens Main Motor

Tele mecanique/Schneider Electrics

Hydraulic &Electrical overload protection

Top and Bottom Tooling(86°,R0.6mm)

Safety Standards(2006/42/EC):

Safety Equipment:

1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

Front finger Protection(Safety light curtain)

South Korea Kacon Foot Switch(Level 4 of safety)

Back metal safe fence with CE standards

Safety relay with Monitor the pedal switch and safety protection

Product Features

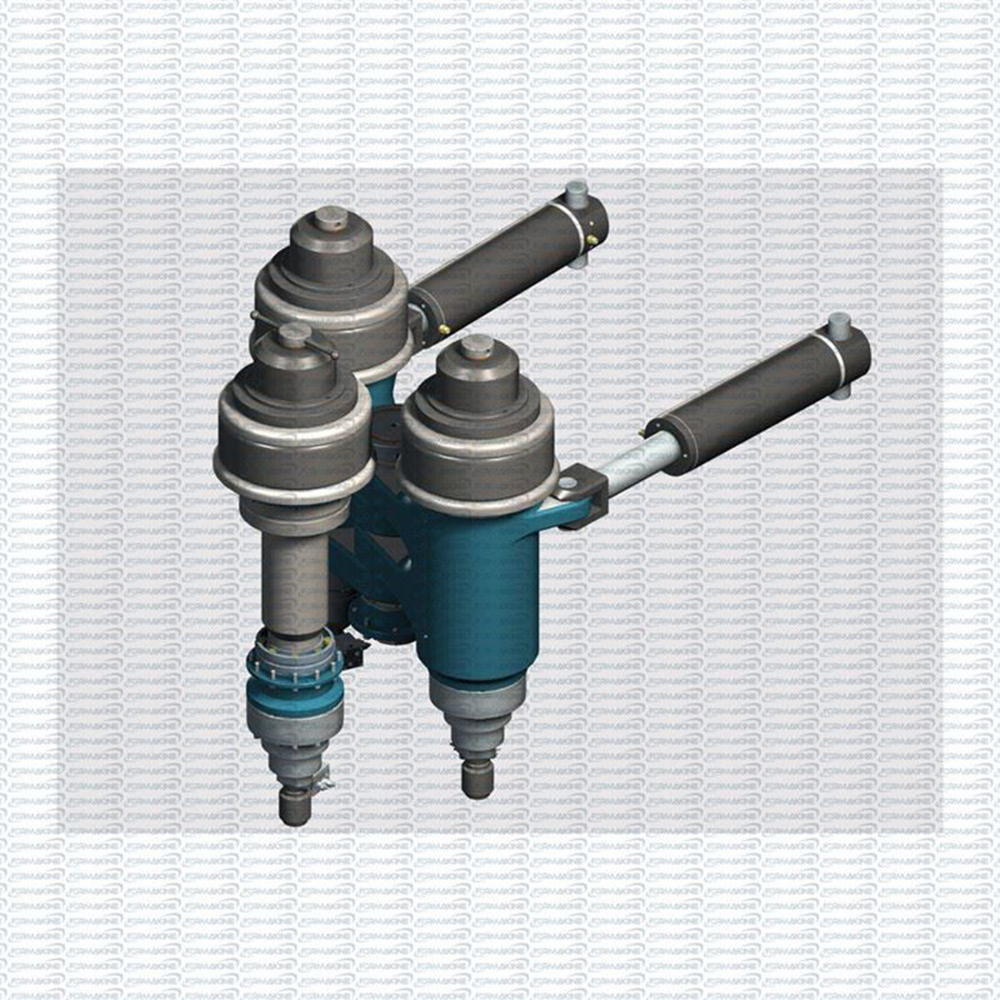

The use of hydraulic pressure of the three Main shaft driver and curvature gives stabilization to the machine.

The adoption of grating ruler makes curvature adjusting scope more precise and convenient.

The touching control screen and PLC electrical control system of SIEMENS is used and has bilingual system which is Chinese and English.

Has auto-detecting system and alarm. The screen can prompt all error information and solutions.

Can counting the process amount at any moment.

All bending destiny can save in PLC for ever and use it at any time.

Possess the function of manual and automatic operation. The powerful cooling system ensures the machine stable working in hot area.

Can process varies of metal material like angle iron, flat steel, round pipe and other material of different section if change the groove of bending dies.

Avoiding the abuse of processing outsize tube is necessary supplement of one head and double head pipe bender.

Technical Parameters

| Model | W24S-6 | W24S-16 | W24S-30 | |

| Max. Anti-Winding Cass-Section Molds (Cm3) | 6 | 16 | 30 | |

| Winding Speed (M/Min) | 4 | 3 | 3 | |

| Yield Strength (MPa) | 250 | |||

| Angle SteelInternal Winding | Max. Cross – Section(Mm) | 40*5 | 70*8 | 75*10 |

| Min. Winding Die. (Mm) | 800 | 1000 | 1200 | |

| Min. Cross - Section(Mm) | 20*3 | 30*3 | 35*3 | |

| Min. Winding Die. (Mm) | 400 | 550 | 560 | |

| Angle SteelEternal Winding | Max. Cross – Section(Mm) | 50*5 | 75*10 | 90*10 |

| Min. Winding Die. (Mm) | 800 | 1000 | 1100 | |

| Min. Cross - Section(Mm) | 20*3 | 30*3 | 35*3 | |

| Min. Winding Die. (Mm) | 400 | 550 | 500 | |

Production Configuration

| No. | Items | Brand |

| 1 | Machine Main Body | FORMAKINE Professional Welding, Post Weld Stress Relief Treatment |

| 2 | Painting | Sand Blasting Treatment, Surface Spray Powder, Color Can Be Customized. |

| 3 | PLC | Omron Or Taian |

| 4 | Frequency Converter | Mitsubishi Or Delta |

| 5 | Servo Motor | Elesy |

| 6 | Touch Screen | KINCO |

| 7 | Encoder | Omron |

| 8 | Low Voltage Apparatus | Schneider |

| 9 | Ball Screw | Hiwin |

Picture Display

Suggestion

Sample

Certificate & Logistics