Front Feeding Hydraulic Shearing Machine

Product Introduction

CE&SGS&ISO CERTIFICATED QC11KQ-6X3200 Front Feeding Hydraulic Shearing Machine

QC11Y-12X3200 Hydraulic Plate Guillotine Cutting Machine/cutting Machine Factory/shearing Machine Factory

Product Features

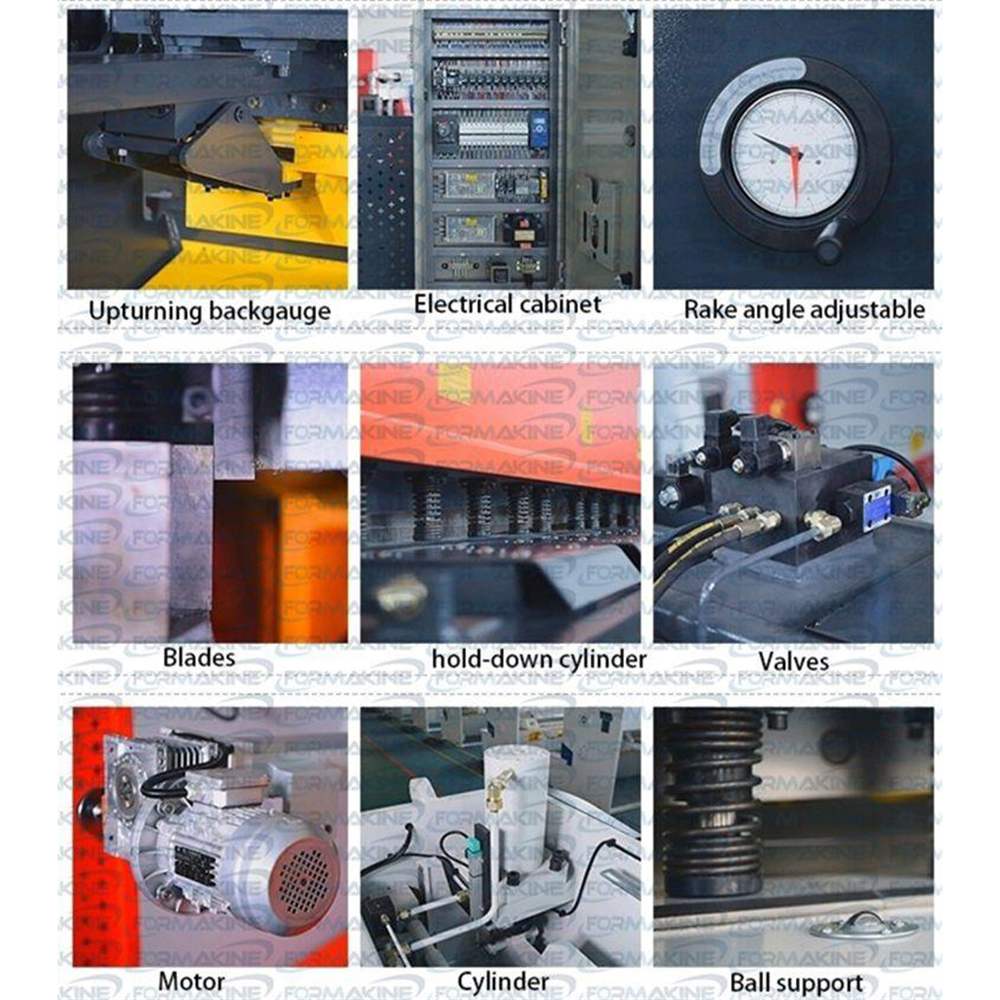

Welded steel plate construction, eliminate internal stress by heat treatment, with high strength and good rigity.

Advanced integrated hydraulic system with an excellent reliability.

Rapidly, accurately and conveniently adjusting the blade clearence with the handweel.

The rectangular blades featuring long lifetime with 4 cutting edges

As the cutting beam has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed.

European key electrics

Light alignment device eases drawing line for cutting

Standard front support sheet frame

A set of standard blade

QC11Y-12X3200 CNC Guillotine shear parameters:

Max cutting thickness: 6mm;

Working length 3200 mm;

Shearing angle:0.5°~1.5°

Throat depth 80mm;

Strokes:12 times/min;

Control system: ESTUN; SIKO; DELEM; WONDER; MAPER, can made according to customer requirements

Electrics

Main power 7.5KW;

Back gauge travel :750mm

Main Equipments:

Hydraulic system:First, from USA;

Blades: 6Crw2si;

Pump: Gear pump;

Electrics: Schneider from France;

O-rings: Japanese NOK

Optional devices for customers:

1. stainless steel front cover 2. Front 1m protection Pneumatic devices 3. cutting angle indication lights 4. electic blade gas adjustment set 5. rear protection rail with ABB satety switch 6. Linear Guides or ball screw 7. Machine body color optional also 8. Sumitomo pump and siemens motor optional 9. Rear pneumatic unloading device. 10: Blade with Cr12MoV , 9CrSi

Technical Parameters

|

Type |

Cut Thickness |

Cut Length |

Shear Angle |

SPM |

Back Gauge |

Throat Depth |

Main Motor |

Net Weight |

Outline Size (L*W*H) |

|

Mm |

Mm |

Degree |

Min-1 |

Mm |

Mm |

Kw |

Kg |

Mm |

|

|

MS7-4*2500 |

4 |

2500 |

1°30' |

≥22 |

600 |

100 |

5.5 |

4650 |

3300*1600*1700 |

|

MS7-4*3200 |

4 |

3200 |

1°30' |

≥18 |

600 |

100 |

7.5 |

4950 |

3950*1600*1700 |

|

MS7-4*4000 |

4 |

4000 |

1°30' |

≥12 |

600 |

100 |

7.5 |

6900 |

4600*1705*1600 |

|

MS7-6*2500 |

6 |

2500 |

1°30' |

≥16 |

600 |

120 |

7.5 |

5140 |

3150*1500*1600 |

|

MS7-6*3200 |

6 |

3200 |

1°30' |

≥12 |

600 |

120 |

7.5 |

6250 |

4000*1700*1800 |

|

MS7-6*4000 |

6 |

4000 |

1°30' |

≥10 |

600 |

120 |

7.5 |

8520 |

4650*1700*1800 |

|

MS7-6*6000 |

6 |

6000 |

1°30' |

≥7 |

600 |

120 |

11 |

17000 |

6780*2450*2100 |

|

MS7-8*2500 |

8 |

2500 |

1°30' |

≥14 |

600 |

120 |

7.5 |

5900 |

3180*1680*1700 |

|

MS7-8*3200 |

8 |

3200 |

1°30' |

≥12 |

600 |

120 |

7.5 |

6500 |

4000*1800*1850 |

|

MS7-8*4000 |

8 |

4000 |

1°30' |

≥10 |

600 |

120 |

11 |

7360 |

4680*1800*1850 |