CNC Copper Tube Bending Machine

Product Description

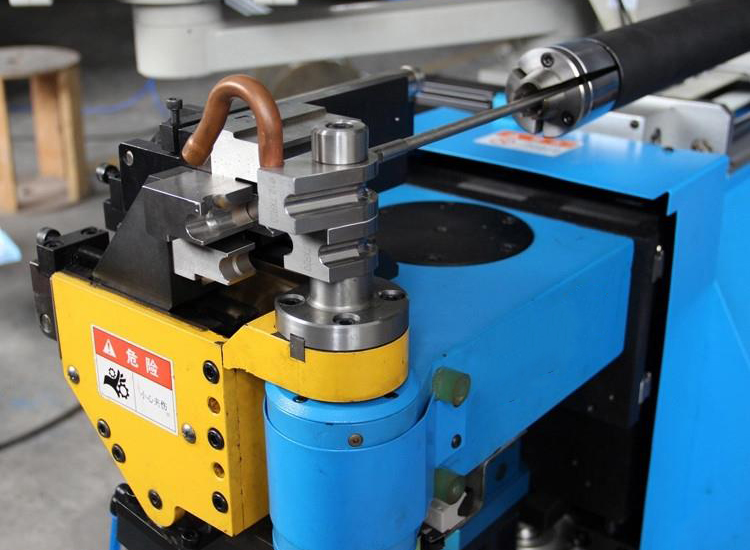

Main Features Of CNC Copper Tube Bending Machine

1)The machine frame and body adopt keel structure to ensure machine with high intensity, rigidity, and stability.

2) The bending head is designed in integral box structure and bending arm adopts precise teeth chain as transmission, high precision.

3) Special clamping structure ensures enough clamping force, not to damage workpiece.

4) The core rod is of universal joint type, exempting from lubrication.

5) Machine has self-testing function for detecting original of X and Z axis and dead point alarming.

6) 8” LCD displayer, integrative antifouling keyboard.

7) CNC controller can save 400 units programs for 400 products, G-M code, with RS232 interface.

8) Program has auto-calibration function for bending angle and length, auto counting, auto alarming, power-off memory.

9) There is option of dual-die auto shifting copper tube bending machine.

Technical Parameters

| Item | Data | ||

| Suitable Bending Tube Diameter | Copper/Aluminum | Max. 20mm | |

| Carbon Steel | Max. 16mm | ||

| Suitable Tube Wall Thickness | Copper/Aluminum | Max. 1.5mm | |

| Carbon Steel | Max. 1.0mm | ||

| Max. Bending Angle | 0- 200º | ||

| 3D Rotating Angle | 360º | ||

| Max. Bending Radius | R80mm | ||

| Min. Bending Radius | R10mm | ||

| Max. Workpiece Length | 1800mm (Through-Type) | ||

| Feeding Stroke | 0-1200mm | ||

| General Bending Efficiency | 2.2 Sec. Per Bend | ||

| Feeding Speed | 1-1200mm/Sec. | ||

| Rotating Speed | 0-600 º/Sec. | ||

| Bending Speed | 0-300 º/Sec. | ||

| Re-Positioning Precision | Feeding Axis | ±0.05mm | |

| Rotating Axis | ±0.05º | ||

| Bending Axis | ±0.05º | ||

| Servo Motor Power | Feeding Axis | 1.5kW | |

| Rotating Axis | 0.75kW | ||

| Bending Axis | 3.0kW | ||

| Pneumatic Pressure | 0.5-0.7MPa | ||

| Power Supply | 380V, 3Phase, 50Hz | ||

| Machine Dimension | 2500 X 620 X 1300mm | ||

| Weight | About 1200kg | ||

Main Components

- CNC controller: self-made CNC control system

- Servo motors and drivers: Mitsubishi from Japan

- Ball screw and linear guide: THK from Japan

- Approaching switches & sensors: Autonics from Korea

- Circuit breaker: Fuji from Japan

- Main bearings: NSK from Japan

- Buttons: Schneider

Our Factory

Transportation & Packing